The metal industry places great importance on the recycling of PGMs, or platinum group metals, due to the growing demand for these expensive metals in a variety of industrial applications. However, there are possibilities and problems unique to the recycling process. In this piece, we’ll examine the steps involved in PGM recycling, the difficulties recyclers encounter, and the prospects for long-term expansion in this industry.

PGM Recycling Processes

PGM recycling consists of many steps, all of which are designed to extract and refine precious metals from waste materials:

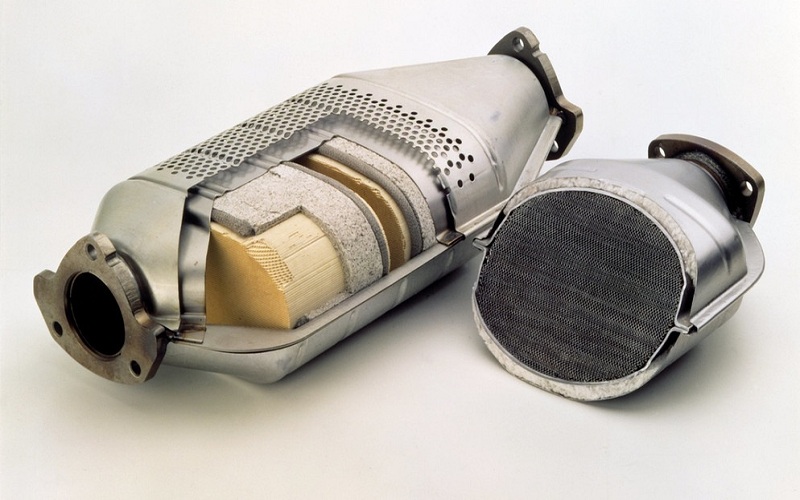

Collection: Scrap items, including PGMs, such as jewellery, electronic components, and catalytic converters, are gathered from various sources, such as recycling facilities, end-of-life cars, and electronic garbage.

Sorting and Preparation: The gathered scrap materials are sorted to distinguish PGM-containing components from other materials. After the removal of non-metallic components, the scrap is ready for processing.

Processing: Scrap containing PGMs is processed to recover precious metals. Mechanical techniques like shredding and grinding break down materials, and then the metals are dissolved and recovered by chemical techniques like smelting or leaching.

Refining: To make the recovered PGMs pure and free of contaminants, they go through refining. Depending on the type of metals being handled, refining techniques may include electrolysis, precipitation, or distillation.

Difficulties with PGM Recycling

PGM recycling is important; however, it confronts a number of obstacles:

Complexity of Materials: Because of their varied compositions and the presence of impurities, scrap materials containing PGMs, such as catalytic converters, can be complicated and challenging to handle.

Poor Recycling Rates: Despite their high intrinsic value, platinum group metals (PGMs) have very poor recycling rates compared to other materials. Many goods that contain PGMs are not recycled; instead, they wind up in landfills.

Market Volatility: Due to supply limits, geopolitical issues, and market demand, PGM prices—especially those of platinum, palladium, and rhodium—are prone to large swings. This volatility may impact the profitability of the PGM recycling industry.

Environmental Risks: If improperly handled, certain PGM recycling processes, such as smelting, can produce harmful byproducts and pollutants that could threaten the environment.

Prospects for Development

Notwithstanding the difficulties, PGM recycling offers a number of chances for long-term, sustainable growth:

Technological Developments: The application of recycling technologies, such as enhanced extraction procedures, better sorting strategies, and cleaner refining techniques, may increase the sustainability and efficiency of PGM recycling.

Initiatives for the Circular Economy: Adopting the concepts of the circular economy can encourage PGM recycling and reuse, lowering the need for primary sources and minimising the negative effects on the environment.

Economic Incentives: The growing demand for PGMs in developing technologies like fuel cells and renewable energy systems makes investing in PGM recycling and growing market potential more attractive.

Regulatory Support: Reducing dependency on primary raw material sources and promoting recycling are two goals that governments and regulatory agencies are progressively putting into practice. Businesses that recycle PGMs may find it advantageous to support these projects.

Partnerships and Collaboration: Working together, manufacturers, recyclers, and legislators may enhance recycling infrastructure, spur innovation, and solve shared issues amongst PGM supply chain participants.

Conclusion

PGM recycling is essential to resource conservation, environmental impact reduction, and satisfying the rising demand for these priceless metals. The industry can expand thanks to technical advancements, circular economy efforts, financial incentives, regulatory assistance, cooperation, complicated materials, poor recycling rates, and market instability. By tackling these issues and taking advantage of available possibilities, the PGM recycling sector can help create a more successful and sustainable future.